General Applications

CLEANING

It is the most traditional blasting application and everyone knows its efficiency. However, with modern operating techniques, the development of new equipment and the advent of special materials, the field has expanded to unpredictable areas. With glass balls or walnut shells, for example, high precision parts can be blasted without the slightest dimensional change. Today, from cleaning cobalt chromium alloys in dental prostheses, ship hulls, carburetors or molds in general, airplane wheels, etc. can be cleaned with blasting. Virtually all industry sectors are potential users of the process, even for general maintenance.

FINISHING

Blasting cannot polish a surface. It is possible, using the correct specifications, to clean without damaging the polish. What can be achieved is a uniform and controlled matting which is a valid, very beautiful and inexpensive type of finish. With glass beads, the surface is satin-like, smooth to the touch, and is especially recommended for stainless steel as it does not contaminate it. In many parts unwanted polishing – firearms, optical and surgical instruments, windshield wipers and car dashboard components – and the process is the most economical solution. In many cases it can replace chemical texturing for pattern matting. Other common explanations are: glossing off plastics, matting glass, smoothing surfaces before polishing, and so on.

BREAKDOWN

It is the most traditional blasting application and everyone knows its efficiency. However, with modern operating techniques, the development of new equipment and the advent of special materials, the field has expanded to unpredictable areas. With glass balls or walnut shells, for example, high precision parts can be blasted without the slightest dimensional change. Today, from cleaning cobalt chromium alloys in dental prostheses, ship hulls, carburetors or molds in general, airplane wheels, etc. can be cleaned with blasting. Virtually all industry sectors are potential users of the process, even for general maintenance.

RECORDING OR DECORATION

Blasting cannot polish a surface. It is possible, using the correct specifications, to clean without damaging the polish. What can be achieved is a uniform and controlled matting which is a valid, very beautiful and inexpensive type of finish. With glass beads, the surface is satin-like, smooth to the touch, and is especially recommended for stainless steel as it does not contaminate it. In many parts unwanted polishing – firearms, optical and surgical instruments, windshield wipers and car dashboard components – and the process is the most economical solution. In many cases it can replace chemical texturing for pattern matting. Other common explanations are: glossing off plastics, matting glass, smoothing surfaces before polishing, and so on.

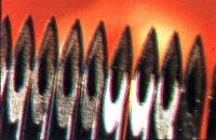

SHOT PEENING

It is a modern technique of cold treatment of metallic surfaces. It is a kind of “hammering” obtained by spherical particle jetting, usually of glass or steel, that improves the surface metallurgical qualities in order to increase the resistance to mechanical and thermal fatigue, overheating, corrosion among others. Other effects, such as sealing surface microporosity, elimination of micro cracks or directional machining hazards, which are stress concentration points, open to the process a wide range of applications such as cutting tools, stamping, flat or coil springs, crankshafts, connecting rods and hundreds of other parts subjected to alternating stress or friction. Shot peening requires rigorous application and automation specifications, but the benefits, often with exponentially greater results, justify their use.

-

Phone

+55 (11) 3388-3534

-

Rua Muniz de Souza, 306

Aclimação, São Paulo - SP

-

E-mail:

zirtec@zirtec.com.br