Turbines

They are rotary devices provided with blades that accelerate by centrifugation particles of abrasives fed continuously by the center. They are much more energy efficient than suction guns and pressure nozzles, ie with the same power installed they can perform a much larger service volume.

They are rotary devices provided with blades that accelerate by centrifugation particles of abrasives fed continuously by the center. They are much more energy efficient than suction guns and pressure nozzles, ie with the same power installed they can perform a much larger service volume.

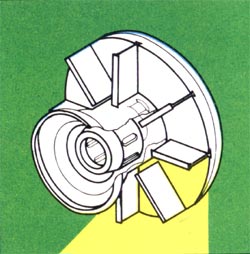

Basically they are composed of a radial vane rotor that generally rotates between 1500 and 3000rpm. , and a metering valve that can regulate the volume fed and the direction of this feed in the center of the turbine.

Depending on the angle at which the abrasive is released into the turbine, it is fan-thrown over a given area, ie the flow can be directed with some precision. The most commonly used abrasives in turbines are spherical steel grits, but they can also operate on lighter ones, including walnut shells.

Depending on the purpose they are manufactured with various diameters in the range of 150 550mm with also varying widths.

Rated power absorbed from a compressed air network for new nozzles. For a compressor directly connected to the pressure vessel, capacities of 15 to 20% higher are recommended.

Comparative reference to the production of the 1/8 ”diameter pressure nozzle.

Just to illustrate the efficiency, it is worth mentioning that a 550mm diameter turbine, rotating at 2600 rpm, driven by a 75hp engine throws over 600kg / min. of steel shot.

Just to illustrate the efficiency, it is worth mentioning that a 550mm diameter turbine, rotating at 2600 rpm, driven by a 75hp engine throws over 600kg / min. of steel shot.

Just to illustrate the efficiency, it is worth mentioning that a 550mm diameter turbine, rotating at 2600 rpm, driven by a 75hp engine throws over 600kg / min. of steel shot.

They are constructed from special alloys of high abrasion resistant steel, which ensures wear parts have over 300 hours of service life.

In the drawing, the shape of the array of thrown abrasives covering an elongated area that may be more than one meter long is outlined.

The large surface area associated with the high volume of material thrown at high speeds gives turbines a wide range of applications, usually for large parts such as sheet and profile stripping, forged or castings (with or without sand), bar shot peening. of torsion etc.

Since it was developed more than 100 years ago, the blasting process has always proved to be a highly efficient resource and its applications have multiplied rapidly and are even absorbed by various industrial sectors.

However, application technology was primitive, with three basic drawbacks:

– Environmental pollution, creating problems of dusty atmosphere that hit and damaged buildings and even machinery inside, as well as the health of operators.

– Even with the development of more efficient and less polluting abrasives, their use was prohibitive due to the difficulties of their recovery.

– Finally, even recovered, these abrasives gradually contaminated, impairing the repeatability and efficiency of the process.

Solutions have emerged and improved over a century of evolution, radically changing the image of blasting equipment, once relegated to the confines of factories, today found on production lines, alongside sophisticated conventional mechanical equipment, fully meeting the most stringent safety requirements and uniformity of production.

Open-air operations tend to disappear completely not only because of pressure from official or internal company security bodies, but also for economic reasons regarding direct costs, transportation and operational efficiency.

The modern design of blasting equipment always includes, with greater or less sophistication, the following components:

1) Confinement of the blasting operation itself

Accelerated particles (suction guns, pressure nozzles, turbines, etc.) and the parts on which they fall are always confined indoors as simple cabinets or large booths into which operators also enter environments.

2) Abrasive pickup

They are gravity, mechanical or pneumatic devices that collect and concentrate the materials in silos, returning them to the process.

3) Abrasive Scrubbers

They are intermediate devices of greater or less complexity according to the operational requirements, which remove from the materials, after blasting, the contaminations removed, the operational dust and eventual larger debris, returning them to the process with constitution and granulometry similar to the initial ones.

4) Exhaust Systems

Its main function is to drag dust from confined environments and separate them from abrasives. When properly sized, they ensure good internal visibility and decompression (negative pressure) on all system components, increasing safety against dust leakage into the outdoor environment.

5) Dust collectors

They separate the exhaust air from the dust, trapping it and returning the first purified to the atmosphere.

-

Phone

+55 (11) 3388-3534

-

Rua Muniz de Souza, 306

Aclimação, São Paulo - SP

-

E-mail:

zirtec@zirtec.com.br