Equipment and Devices

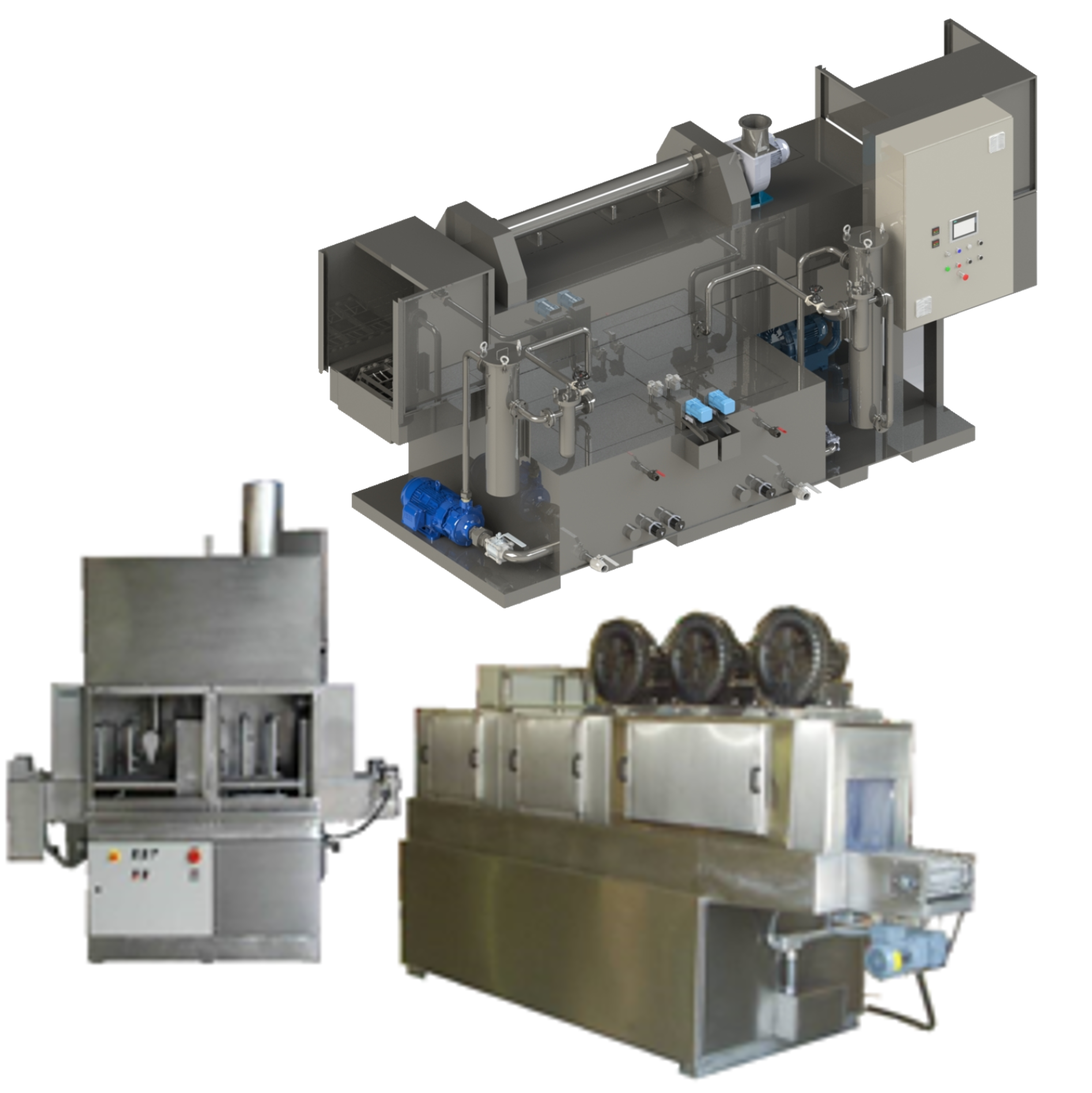

Zirtec has been trading and manufacturing washers since 1994 and has rotary table, drumming, treadmill and mini treadmill equipment for production cells, dipping, ultrasound, high pressure (up to 20,000 psi), special retrofitting equipment and devices on request.

|

WASH MACHINES

|

|

WASH MACHINES

|

|

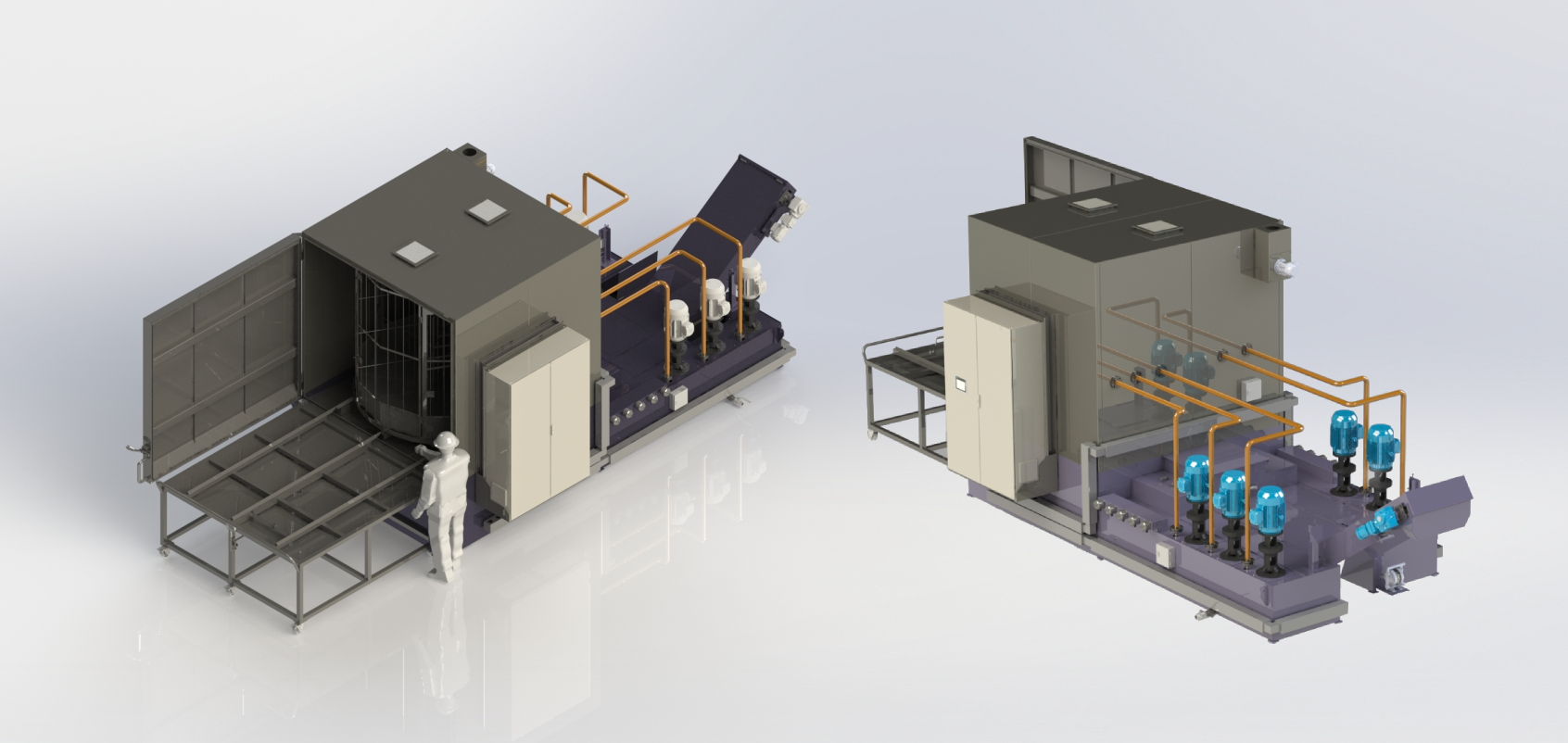

MEGA WASH

|

|

DIP WASHERS WITH MULTI STAGES

|

|

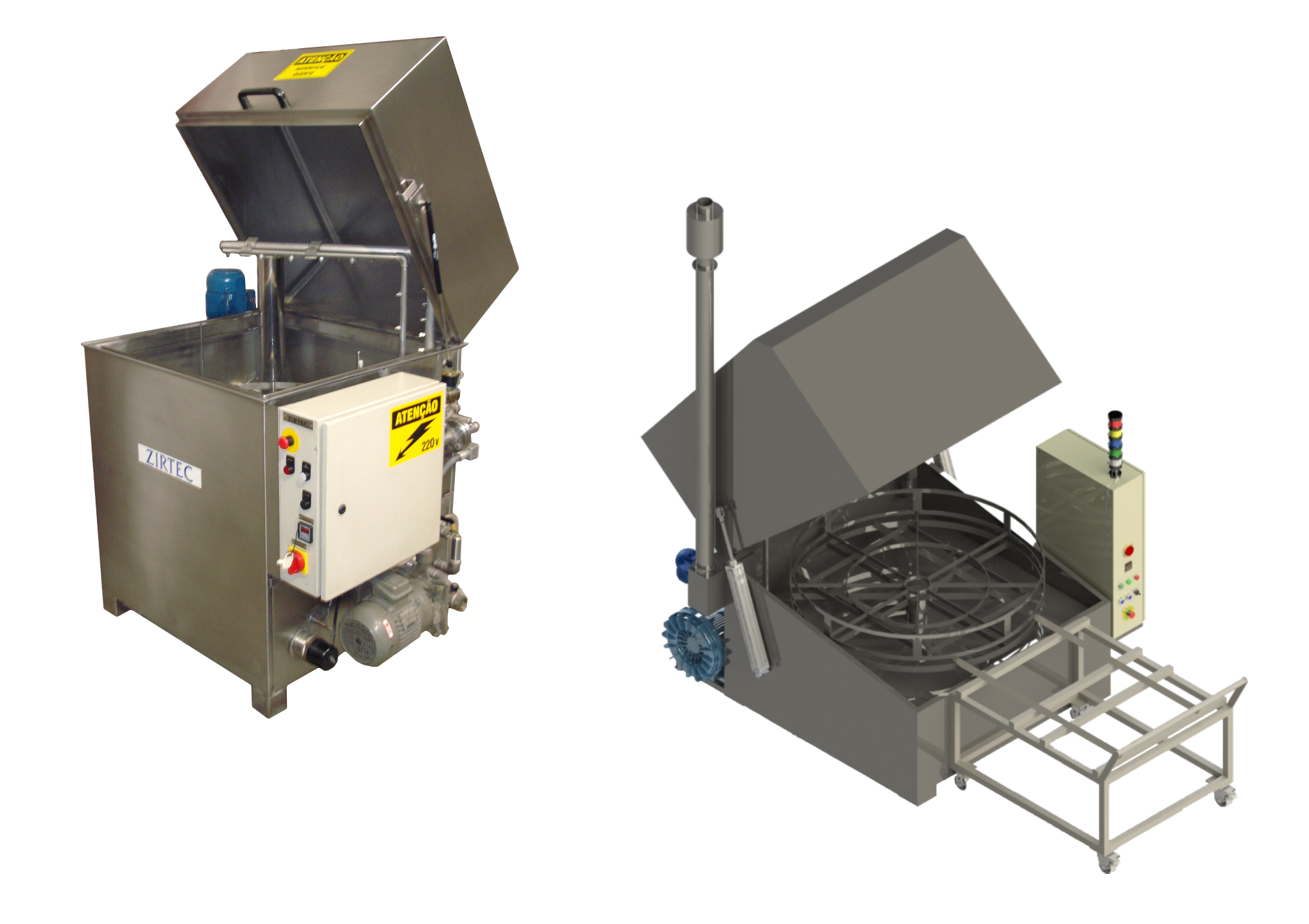

Zirclean 420Description: Compact Production Cell Washer Table or drum diameter = 420 mm Height = 400 to 1,000 mm Permissible weight = up to 100 kg Power = from 1.0 hp to 10 hp. |

|

Zirclean 620Description: Compact washer for high production Table or drum diameter = 620 mm Height = 600 to 1,000 mm Permissible weight = up to 150 kg Power = from 1.0 hp to 10 hp |

|

Zirclean 820Description: Compact washer with wash stages, up to two rinses and drying. Table diameter = 820 mm Larger diameters up to = 1,800 mm (on request) Height = 500 to 1,400 mm Permissible weight = up to 200 kg Power = from 1.0 hp to 10 hp |

|

Z 700

|

|

Z 1420Y

|

|

ECO 750

|

|

ECO 750 SLIDING DOOR

|

|

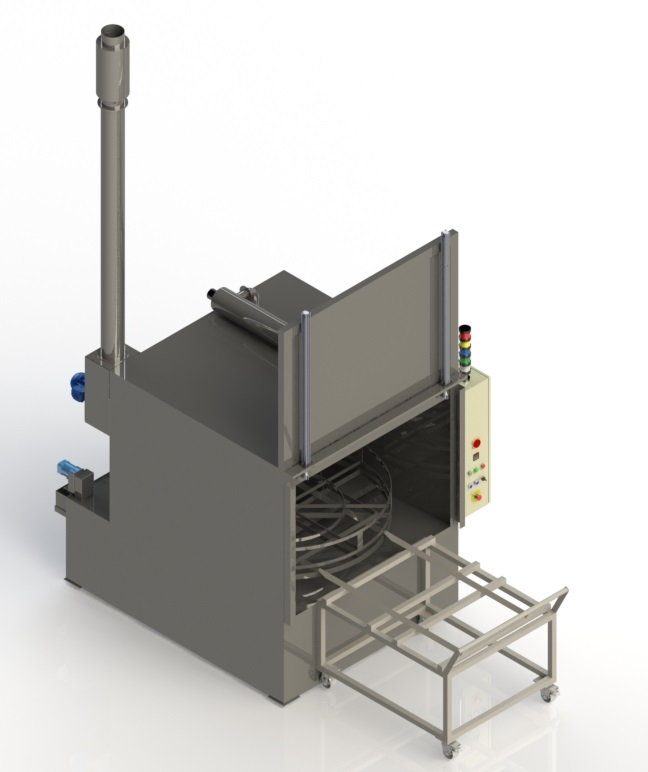

LAV PRO

|

|

WASHERS WITH MOTION (OVAL)

|

|

DRESSING WASHERSWith drum diameter from 400 to 1,300 mm. |

|

OILER

|

|

PARTS COOLER

|

|

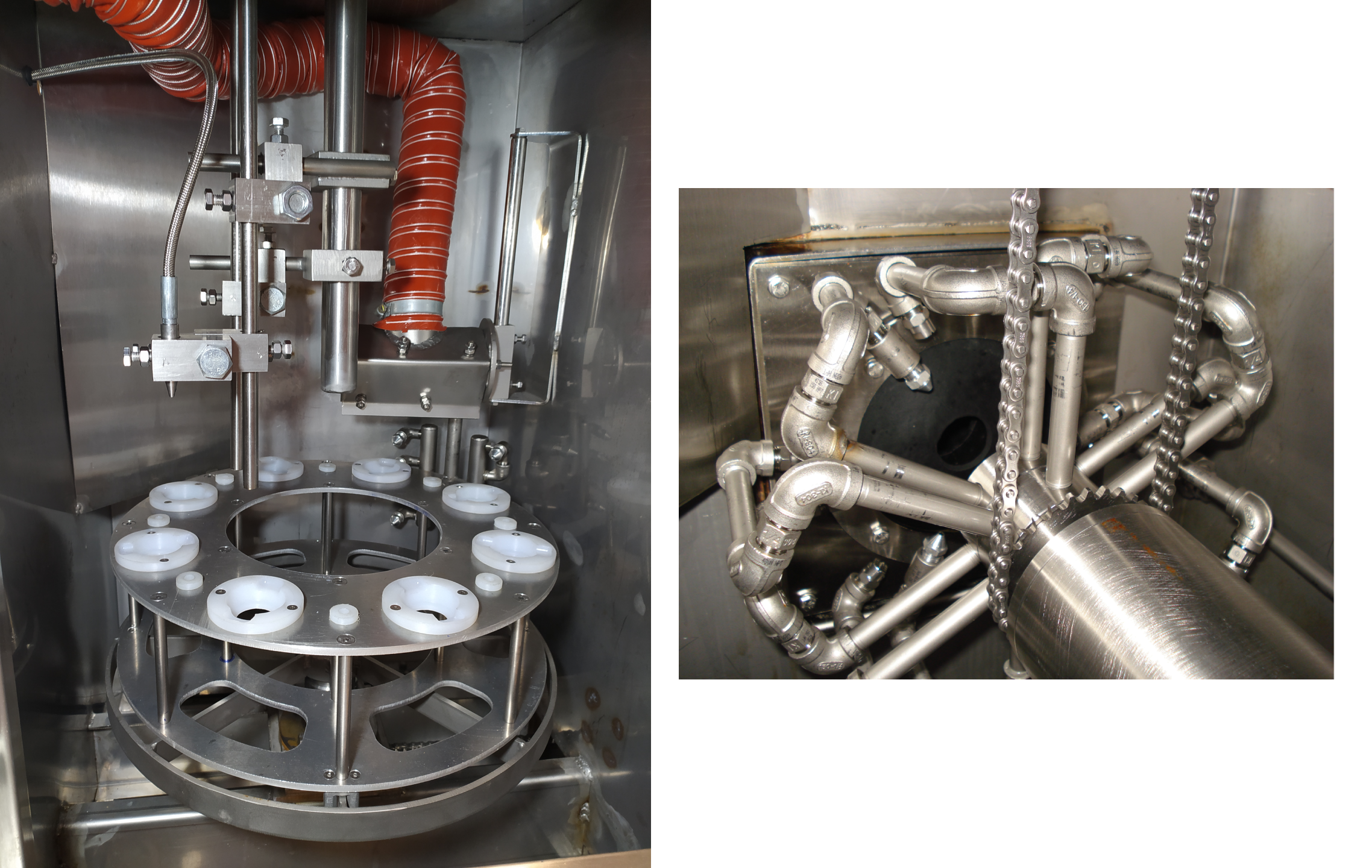

DEVICESZirtec devices are designed and customized according to the geometry, dimensions and cleaning specifications of each item, according to each customer's needs for the best cleaning and drying quality.; |

|

DEVICESThe projects aim to provide the best ergonomics for loading and unloading and the POKA YOKE system that guarantees the best positioning during the washing and drying operation. |

|

RETROFITTINGZirtec has the engineering and manpower to retrofit providing equipment upgrades and modernization including to NR 12. Contact us. |

-

Phone

+55 (11) 3388-3534

-

Rua Muniz de Souza, 306

Aclimação, São Paulo - SP

-

E-mail:

zirtec@zirtec.com.br