Aluminum Oxide

Characteristics

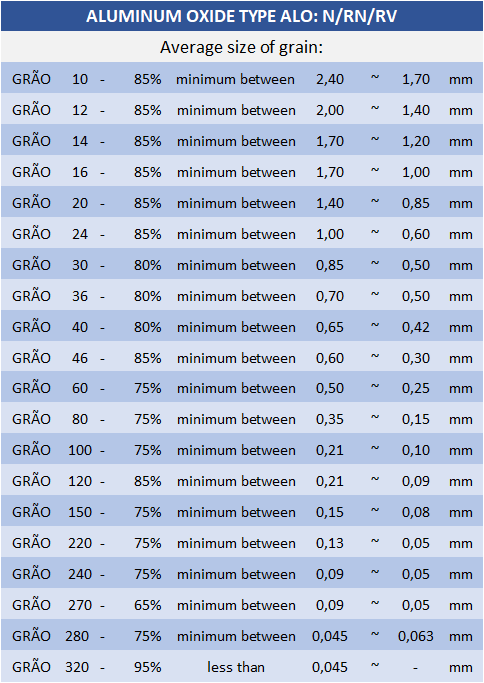

Aluminum oxide is a product obtained artificially by melting in electric furnaces and slow cooling of Bauxite and subsequently ground and classified into various types and granulometry. It is a material of high hardness (9 on the Mohs scale), with specific weight of 3.2g/cm3 and the grains have sharp edges. For blasting, the most used type is the so-called Oxide of First, dark gray color and classified in several granulometries.

Aluminum oxide can have several levels of purity (AL²O³ content), thus varying its color and application.

Applications

The physical, chemical and geometric characteristics of the grains, associated with the commercial availability of regular classifications, open to aluminum oxide, a wide and peculiar field of application in blasting.

The process is highly abrasive which is an important quality for some applications:.

– Removal of very hard scale;

– Preparation of surfaces for malting, electroplating and painting and controlled roughness for anchoring, especially in parts of high surface hardness;

– For the same reasons, it is also used to prepare surfaces for adhesion of high responsibility coatings;

– In addition to good cleaning quality, some types of surface imperfections can be reduced or even eliminated.

In certain cases, the chemical composition of aluminium oxide and the absence of certain types of contamination form the blasting process compatible with some applications:

– Cleaning of titanium for plasma adhesion, widely used in industry and aeronautical maintenance;

– cleaning of noble alloys such as chromium cobalt in dental prostheses;

– General cleaning of non-ferrous metals, even precious ones, when possible contamination with silica (sand) or iron (sand and steel grit) is not permissible.

In addition to cleaning, other applications with deburring and satin finish can be obtained with aluminum oxide blasting and will be treated in later information.

For very special applications, such as in the dental or orthopedic field for example, other types can be employed more purified or classified into finer granulometries.

Finer grain sizes available in stock. Consult us.

-

Phone

+55 (11) 3388-3534

-

Rua Muniz de Souza, 306

Aclimação, São Paulo - SP

-

E-mail:

zirtec@zirtec.com.br